Products > Completion Tools

|

Rope Socket-Pear Drop Type For Slick Line |

1.25",1.5",1.875",2.125",2.25",2.5" |

|

Rope Socket-Disc/Spring Type |

1.25",1.5",1.875",2.125",2.25",2.5" |

| Rope Socket-Slip Type For Braided Line | 1.25",1.5",1.875",2.125",2.25",2.5" |

|

Swivel Joint |

1.25",1.5",1.875",2.125",2.25",2.5" |

|

Stem-Standard |

1.25",1.5",1.875",2.125",2.25",2.5" |

|

Stem-Lead Filled |

1.25",1.5",1.875",2.125",2.25",2.5" |

| Stem-Tungsten | 1.25",1.5",1.875",2.125",2.25",2.5" |

| Stem-Roller | 1.25",1.5",1.875",2.125",2.25",2.5" |

| Accelerator | 1.25",1.5",1.875",2.125",2.25",2.5" |

| Link Jar | 1.25",1.5",1.875",2.125",2.25",2.5" |

| Tubular Jar | 1.25",1.5",1.875",2.125",2.25",2.5" |

| Spring Jar | 1.25",1.5",1.875",2.125",2.25",2.5" |

| Hydraulic Jar | 1.25",1.5",1.875",2.125",2.25",2.5" |

| Tubular Jar | 1.25",1.5",1.875",2.125",2.25",2.5" |

|

PCE PCE breech Lock Connector |

1.25",1.5",1.875",2.125",2.25",2.5" |

|

BDK Heavy Duty Q.R .J |

1.25",1.5",1.875",2.125",2.25",2.5" |

|

Knuckle Quick Joint |

1.25",1.5",1.875",2.125",2.25",2.5" |

|

X-Over |

1.25",1.5",1.875",2.125",2.25",2.5" |

|

Knuckle Joint |

1.25",1.5",1.875",2.125",2.25",2.5" |

|

Heavy Duty Knuckle Joint |

1.25",1.5",1.875",2.125",2.25",2.5" |

| Spring Centraliser | 1.5",1.875",2.125",2.25",2.5" |

| Fluted Centralizer | 1.5",1.875",2.125",2.25",2.5" |

| Roller Centralizer | 1.5",1.875",2.125",2.25",2.5" |

| Supported Roller Centraliser | 1.75",1.875",2.125",2.25",2.5" |

|

Fluted Centralizer-Stepped Slip Over |

2.5",2.75",3",3.5" |

--------------------------

Coiled Tubing Tools

Introduction

Double Slip Connector

1. Introduction

Double slip connector is a tool to quickly connect downhole tools to coiled tubing. Double slip connector is different from conventional connector, double slip lock rings make sure the tool lock to the coiled tubing, no need for buckle. Two slip rings can share the load and improve the reliability, two O-rings to seal tubing string.

2. Feature

Easy to install , and quick to connect.

The slip lock ring applies redundant design, which improves the reliability

Large load capability

Double O-ring seal

3. Application

Double slip connector suit for all coiled tubing down hole tools

High torque load, can be connected to mud motor

High strength connection application

Remove one lock ring and use as single connector

| CT | Number | Max Diameter | Min Diameter | Pressure | Tensile | Anti-torque(I |

| (in) | (mm) | (mm) | (psi) | Strength(Ib) | bf*ft) | |

| 1.250 | L02 175100 | 44.5 | 22.0 | 10000 | 32000 | 700 |

| 1.500 | L02 225100 | 57.0 | 31.0 | 10000 | 55000 | 950 |

| 1.750 | L02 260100 | 66.0 | 38.0 | 10000 | 52000 | 1200 |

| 2.000 | L02 275100 | 70.0 | 44.5 | 10000 | 55000 | 1700 |

| 2.375 | L02 309100 | 78.5 | 48.0 | 8000 | 75000 | 2200 |

| 2.750 | L02 360100 | 91.5 | 61.0 | 9000 | 95000 | 2600 |

Annular pressure connector

1. Introduction

Annular pressure connector is connected with coiled tubing through crimp tool, which make it easier for the coiled tubing connects to down-hole tubing string. Annular pressure connector is suit for all coiled tubing size.

2. Feature

High tensile strength

Double seal inside

Easy connection

Transmissible torque

3. Application

Suit for all coiled tubing size, and can hold high torque

Annular pressure connector crimping tool with two kinds of interchangeable pressure wheel, one wheel is used to crimp arc pressure tubing, another cut-off arc wheel can be used to connect tubing.

| CT(in) | Numeber | Max Diameter | Min Diameter | Pressure | Connection Strength |

| 1.250 | L03 125100 | 31.8 | 8000 | 45000 | 140 |

| 1.500 | L03 150100 | 38.0 | 8000 | 35000 | 140 |

| 1.750 | L03 175100 | 44.5 | 7000 | 50000 | 140 |

| 2.000 | L03 200100 | 50.8 | 7000 | 70000 | 150 |

3

1. Introduction

Screw type connector is a tool to connect coiled tubing and downhole tools / tubing string. It connects coiled tubing through pressing flat screw on the connector to coiled tubing pre-pit. It is pressed through a flat head screw on coiled tubing to connect pre-pits. The pit is prefabricated by special coiled tubing connector tool, which is designed with the screw holes in the same number of connectors and the same position on this special tool, to ensure pre-pits can be accurately connected to the connector.

2. Feature

Dual seal inside

Quick connection and anti high torque

3. Application

Screw type connector is suit for all coiled tubing operations

Connect with mud motor and can hold high torque

| CT(in) | Numeber | Max Diameter | Pressure | Tensile Strength | Connection |

| Strength | |||||

| 1.250 | L05 175100 | 44.5 | 10000 | 45000 | 220 |

| 1.500 | L05 200100 | 50.5 | 10000 | 55000 | 220 |

| 1.750 | L05 225100 | 57.0 | 10000 | 60000 | 220 |

| 2.000 | L05 275100 | 70.0 | 10000 | 80000 | 240 |

| 2.375 | L05 287100 | 73.0 | 10000 | 90000 | 280 |

| 2.875 | L05 337100 | 85.5 | 10000 | 95000 | 280 |

Dual plate check valve

1. Introduction

Dual plate check valve is a standard part of coiled tubing string assembly. when the coiled tubing string or ground equipment is malfunctioning or damaged , double-plate check valve prevent down-hole liquid reflux into the tubing string downhole flow column. Each of plate is double sealed to enhance sealing reality. Elastic sealing mainly provide for low-pressure sealing and high-pressure uses metal sealing.

2. Feature

Each plate with dual seal

Removable plate is easy for maintenance

Full though conduit for pitching ball

3. application

Suite for all coiled tubing operations

Fishing operation

Milling operation

| CT(in) | Numeber | Max Diameter | Min Diameter | Pressure | Connection |

| Strength | |||||

| 1.250 | L06 125100 | 31.8 | 8.0 | 10000 | 305.0 |

| 1.500 | L06 150100 | 38.0 | 10.0 | 10000 | 335.8 |

| 1.750 | L06 175100 | 44.5 | 16.0 | 10000 | 409.0 |

| 2.000 | L06 200100 | 50.8 | 18.0 | 10000 | 414.5 |

| 2.250 | L06 225100 | 57.0 | 25.0 | 10000 | 454.5 |

| 2.375 | L06 237100 | 60.0 | 26.0 | 10000 | 454.5 |

| 2.875 | L06 287100 | 73.0 | 32.0 | 10000 | 478.5 |

1. Introduction

Heavy-load hydraulic safety coupling use lock key connection, it can hold high tension and torque. When needing to disconnect the safety coupling, the use can drop ball to the piston seat. Adding pressure to cut the shearing, piston down, lift column and safety coupling disconnect with clear indication. On the upper neck of downhole tool, there is a standard designed “GS” for fishing.

2. Feature

Hydraulic operation tool

High anti-tensile structure

Anti-torque

Standard fishing neck

Lower head can connect rupture disk as circulation valve

3. Application

Standard coiled tubing operation

Slope well operation

Well cementing and milling operation

| Rupture Disk | ||||||||||

| Number | Pressure | |||||||||

| G0501 | 1000PSI | |||||||||

| G0502 | 2000PSI | |||||||||

| G0503 | 3000PSI | |||||||||

| G0504 | 3500PSI | |||||||||

| G0505 | 4000PSI | |||||||||

| G0506 | 4500PSI | |||||||||

| G0507 | 5000PSI | |||||||||

| CT(in) | Number | Max | Mix | Pressure(psi) | Connection | Fishing | ||||

| Diameter | Diameter | Length(mm) | Swage | |||||||

| (mm) | (mm) | |||||||||

| 1.687 | L07168100 | 42.8 | 12.0 | 10000 | 305.0 | 2 in “GS” | ||||

| 1.750 | L07175100 | 44.5 | 12.0 | 10000 | 335.8 | 2 in “GS” | ||||

| 2.125 | L07212100 | 54.0 | 12.0 | 10000 | 409.0 | 2 in “GS” | ||||

| 2.250 | L07225100 | 57.0 | 20.0 | 10000 | 414.5 | 2 in “GS” | ||||

| 2.375 | L07237100 | 60.0 | 22.0 | 10000 | 454.5 | 2 in “GS” | ||||

| 2.875 | L07287100 | 73.0 | 22.0 | 10000 | 454.5 | 2 in “GS” | ||||

| 3.125 | L07312100 | 79.5 | 27.0 | 10000 | 478.5 | 2 in “GS” | ||||

1. Introduction

Dual circulation valve has dual functions of cutting pin and rupture disc. The valve can circulate by break the rupture disc and provide adequate circulation channels to pump the ball, or drop ball , pressure to shear pins and achieve maximum cycle. Dual circulation valve is applicable to all sizes of coiled tubing operations and can also change rupture disk into screw plug.

2. Feature

Shear pin and rupture disc dual function design accurate rupture disc and shear pin measure setting Large diameter cycle

Suit for all size coiled tubing operation

3. Application

Milling operation

Fishing operation

Well cementing and well washing operation

| Rupture Disk | |||||||||

| Number | Fracture Pressure | ||||||||

| G0501 | 1000PSI | ||||||||

| G0502 | 2000PSI | ||||||||

| G0503 | 3000PSI | ||||||||

| G0504 | 3500PSI | ||||||||

| G0505 | 4000PSI | ||||||||

| G0506 | 4500PSI | ||||||||

| G0507 | 5000PSI | ||||||||

| CT | Max Diameter | Mix Diameter | Pitch | Connection | Pressure | ||||

| Number | Diameter | ||||||||

| (in) | (mm) | (mm) | Length(mm) | ||||||

| (mm) | |||||||||

| 1.687 | L08168100 | 42.8 | 6.35 | 11.0 | 202.5 | 900psi | |||

| 1.750 | L08175100 | 44.5 | 6.35 | 11.0 | 202.5 | 900psi | |||

| 2.125 | L08212100 | 54.0 | 12.7 | 16.0 | 241.0 | 1500psi | |||

| 2.250 | L08225100 | 57.0 | 12.7 | 16.0 | 241.0 | 1500psi | |||

| 2.375 | L08237100 | 60.0 | 12.7 | 16.0 | 241.0 | 1500psi | |||

| 3.125 | L08312100 | 79.5 | 15.8 | 19.0 | 264.0 | 1250psi | |||

7

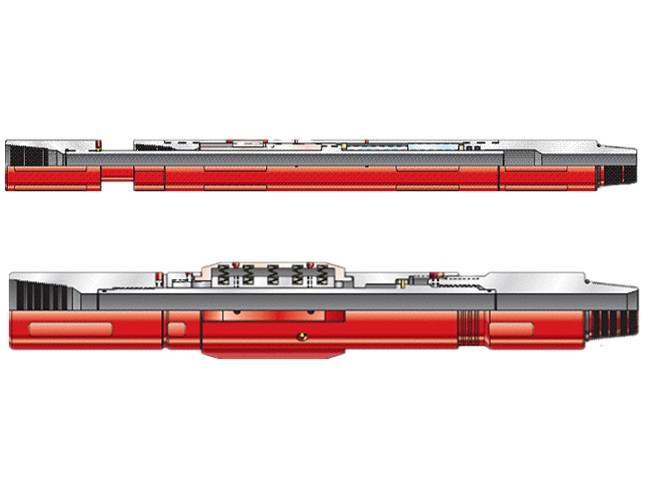

Motor head assembly

1. Introduction

Motor head assembly is a compact coiled tubing assembly. It integrates dual flappers check valve ,hydraulic safety sub and two-way circulation valve, that will convenient for directly usage on well spot.

2. Feature

Shorten the length of tool string

Convenient and fast connection on well site

Hydraulic safety sub can shear on emergency

Establishing circular channels through drop ball to pressure or break the rupture disk

3. Application

For standard coiled tubing operation

| Rupture Disk | ||

| Numeber | Fracture Pressure | |

| G0501 | 1000PSI | |

| G0502 | 2000PSI | |

| G0503 | 3000PSI | |

| G0504 | 3500PSI | |

| G0505 | 4000PSI | |

| G0506 | 4500PSI | |

| G0507 | 5000PSI | |

| Specification(in) | Number | Connection Length(mm) |

| 1.500 | L16 150100 | 470.0 |

| 1.750 | L16 175100 | 470.0 |

| 2.00 | L16 200100 | 533.0 |

| 2.125 | L16 212100 | 533. |

| 2.250 | L08 237100 | 574.0 |

| 3.125 | L08 312100 | 682.0 |

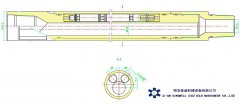

Compact hydraulic jar

1. Introduction

Hydraulic jar (up / down) designed to use with accelerator and flow sub form a coiled tubing short heavy string. The Jar delay device let the energy stored in the stretched and elongated string accelerator, when the energy released will have a great impact force to generate shock effect and loose card tool stuck.

2. Feature

Tool string is short, small diameter, simple structure, reliable, less wear in downhole,, low-cost tools Continuous coiled tubing operation

The same tool can change the components and the direction of the outer cylinder to realize up or down jar Two tools can be connected in series to achieve simultaneously on up or down jar

3. Application

Suitable for fishing, milling and other high risk string card impedance coiled tubing operations This tool can also be used with wire-line tools

| CT(in) | Number | Max Diamete | Mix Diameter | Length | Pressure |

| (mm) | (mm) | (mm) | |||

| 1.812 | L15 181100 | 46.0 | 8.35 | 800.0 | 15000psi |

| 2.375 | L15 237100 | 60.0 | 14.30 | 800.0 | 10000psi |

| 2.720 | L15 272100 | 69.0 | 14.30 | 800.0 | 10000psi |

Anti-torsion hydraulic jar (patent products)

1. Introduction

Hydraulic jar (up / down) designed to use accelerator and flow sub form a coiled tubing short heavy string. The Jar delay device let the energy stored in the stretched and elongated string accelerator, when the energy released will have a great impact, generating shock effect, loose card tool stuck.

2. Feature

Tool is anti-torque and can work with motor

Tool length is short, small diameter, less wear in the downhole Allow a continuous coiled tubing operation

The same tool can change the components and the direction of the outer cylinder to realize up or down jar Two tools can be connected in series to achieve simultaneously on up and down jar

3. Application

Suitable for fishing, milling and other high risk string card impedance coiled tubing operations This tool can also be used with wire-line tools

| CT(in) | Number | Max Diameter | Min Diameter | Length | Pressure |

| (mm) | (mm) | (mm) | |||

| 1.812 | L15 181200 | 46.0 | 8.35 | 1025.0 | 15000psi |

| 2.375 | L15 237200 | 60.0 | 14.30 | 1025.0 | 10000psi |

| 2.720 | L15 272200 | 69.0 | 14.30 | 1025.0 | 10000psi |

Groove centralizer

1. Introduction

Groove centralizer centralizer is designed for downhole coiled tubing string, the tool is designed with diversion groove, the fluid can pass centralizer, the milling cycle generates debris and other debris to the ground. Groove centralizer can be connected to any part of the string.

2. Feature compact structure easy connection low tooling costs

3. Application

Suitable for all standard coiled tubing operations

| CT(in) | Number | Size(in) | Length(mm) |

| 1.500 | L12 150100 | 2.000 | 152.5 |

| 1.750 | L12 175100 | 2.000 | 152.5 |

| 1.750 | L12 175200 | 2.250 | 160.0 |

| 1.750 | L12 175300 | 2.500 | 165.0 |

| 1.750 | L12 175400 | 2.750 | 172.5 |

| 2.250 | L12 225100 | 2.500 | 165.0 |

| 2.250 | L12 225200 | 2.750 | 165.0 |

| 2.250 | L12 225300 | 2.875 | 172.0 |

| 2.250 | L12 225400 | 3.000 | 178.0 |

| 2.250 | L12 225500 | 3.250 | 185.5 |

| 2.250 | L12 225600 | 3.500 | 190.5 |

| 2.250 | L12 225700 | 3.750 | 198.0 |

| 2.250 | L12 225800 | 4.000 | 203.0 |

| 2.875 | L12 287100 | 3.250 | 185.5 |

| 2.875 | L12 287200 | 3.500 | 190.5 |

| 2.875 | L12 287300 | 3.750 | 198.0 |

| 2.875 | L12 287400 | 4.000 | 203.0 |

| 3.125 | L12 3121100 | 4.250 | 210.5 |

| 3.125 | L12 312200 | 4.500 | 216.0 |

| 3.125 | L12 312300 | 4.750 | 223.5 |

| 3.125 | L12 312400 | 5.000 | 228.5 |

| 3.125 | L12 312500 | 5.250 | 236.0 |

| 3.125 | L12 312600 | 5.500 | 241.0 |

| 3.125 | L12 312700 | 5.750 | 249.0 |

| 3.125 | L12 312800 | 6.000 | 254.0 |

11

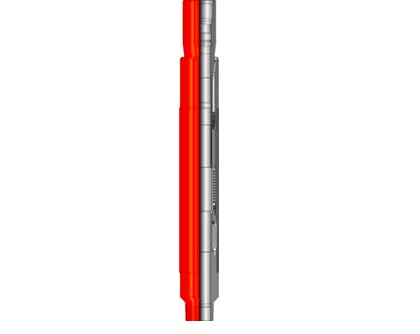

Bow spring centralizers

1. Introduction

Designed for bow spring centralizer centralizer coiled tubing downhole tool string, the bow spring centralizer can be applied to large diameter casing. It can be connected to anywhere in the tool string. Bow springs have large compression range, so that it can not only provide centralizer centralizing force and can go through the small diameter downhole tool.

2. Feature simple structure

Convenient connection and maintenance

3. Application

All standard coiled tubing operations

| CT(in) | Number | Max Diameter(mm) | Min diameter(mm) | Length(mm) |

| 1.750 | L13 175100 | 228.5 | 20.0 | 880.0 |

| 2.000 | L13 175100 | 184.0 | 25.4 | 880.0 |

| 2.125 | L13 212100 | 235.0 | 25.4 | 880.0 |

| 2.250 | L13 225100 | 190.5 | 29.0 | 880.0 |

| 2.375 | L13 237100 | 178.0 | 29.0 | 880.0 |

| 2.500 | L13 250100 | 197.0 | 35.5 | 880.0 |

| 3.125 | L13 312100 | 197.0 | 35.5 | 830.0 |

Venturi fishing basket

1. Introduction

Venturi fishing basket is pump in liquid or nitrogen through coiled tubing and comes into being venturi movement, this movement can collect the debris at the bottom with the suction, the bottom of the bezel can stop debris falling until the tool presented the wellbore.

2. Feature

it can be used to clean wall debris

3. Application

recover or clean wells falling objects and debris high pressure and high temperature environments corrosive environments (NACE MR0175)

| CT | Number | Max Diameter | Min Diameter | Length | Pressure | Thread |

| (in) | (mm) | (mm) | (mm) | |||

| 2.625 | L23262100 | 66.7 | 19.0 | 965.0 | 5000psi | 1.5AMMT.B |

| 3.125 | L23312100 | 79.4 | 25.4 | 1067.0 | 10000psi | 2.375PAC.B |

Hydraulic Retrievable "GS" fishing spear

1. Introduction

Hydraulic Retrievable "GS" fishing spear is designed to fishing downhole tools with standard "GS" fishing diameter. With a small delegation of weight can make spear of "GS" spear jaw locked in well fall within fish salvage path, put on the string can raise off the fish. If the fish can not be stuck down and passed on to mention, then decentralize the string, by circulating fluid can make pull spear fish claw back off, so that the subsequent salvage operation to salvage the string to facilitate smooth proposed. Hydraulic Retrievable "GS" fishing spear has high strength spear design , which can withstand the impact load generated jar. With spear jaw structure , it can securely tightening drop fishing path, but the body is not subject to claw spear tensile load .

2. Feature

It has larger diameter than the traditional "GS" spear

It can be used in jar fishing operations

You can rinse off the fish through the circulation loop of sand or debris

Load acting on the mandrel, the spear that is lower jaw body force

3. Application

Standard fishing operations

Heavy fishing operations

| CT(in) | Numeber | Thread | Min Salvage Inner | Max Salvage Inner |

| Diameter(in) | Diameter(in) | |||

| 1.810 | L24 181100 | 1’’AMMT | 1.345 | 1.625 |

| 2.000 | L24 200100 | 1’’AMMT | 1.600 | 1.750 |

| 2.250 | L24 225100 | 1.5’’AMMT | 1.750 | 2.150 |

| 2.700 | L24 270100 | 1.5’’AMMT | 2.100 | 2.480 |

| 3.000 | L24 300100 | 2.375’’PAC | 2.450 | 2.800 |

| 3.370 | L24 337100 | 2.375’’PAC | 2.800 | 3.000 |

| 3.500 | L24 350100 | 2.375’’PAC | 3.125 | 3.375 |

Hydraulic Retrievable fishing spear

1. Introduction

Hydraulic Retrievable fishing spear is designed with slips spear, which used for fishing smooth fish. With a small delegation of weight can make spear of spear jaw locked in out diameters, put on the string can raise off the fish. If the fish can not be stuck down and passed on to mention, then decentralize the string, by circulating fluid can make pull spear fish claw back off, so that the subsequent salvage operation to salvage the string to facilitate smooth proposed. Hydraulic Retrievable "GS" fishing spear has high strength spear design , which can withstand the impact load generated jar. With spear jaw structure , it can securely tightening drop fishing

| CT(in) | Number | Max Diameter (mm) | Jet Number |

| 1.250 | L32 125100 | 31.5 | 9 |

| 1.500 | L32 150100 | 38.0 | 9 |

| 1.750 | L32 175100 | 44.0 | 9 |

| 2.000 | L32 200100 | 50.5 | 9 |

| 2.375 | L32 237100 | 60.0 | 9 |

| 2.875 | L32 287100 | 73.0 | 9 |

| 3.500 | L32 350100 | 88.5 | 9 |

Ground Cardan joint connector

1. Introduction

This tool is used for quick connection ground coiled tubing, cardan joint structure is easy to facilitate the continuous tubing wrapped around the drum. Tool has small diameter, slips structure can bear high reliability and make the connector capacity,

2. Feature

Simple structure, easy to install on-site

Flexible slip design, easy removal tool

Bearing high strength capacity, stop gear can prevent pipe deformation

Cardan joint design can wrapped ground roller

3. Application

Used for quick connect coil tubing while the ground withstand certain tension. certain tension

| CT(in) | Numeber | Max Diameter | Length(mm) | Tensile Strength |

| (mm) | ||||

| (kn) | ||||

| 1.250 | L41 125100 | 31.5 | 260.0 | 60.0 |

| 1.500 | L41 150100 | 38.0 | 268.0 | 80.0 |

| 1.750 | L41 175100 | 44.0 | 280.0 | 80.0 |

| 2.000 | L41 200100 | 50.5 | 280.0 | 100.0 |

| 2.375 | L41 237100 | 60.0 | 290.0 | 100.0 |

| 2.875 | L41 287100 | 73.0 | 300.0 | 120.0 |

| 3.500 | L41 350100 | 88.5 | 350.0 | 150.0 |

Slip clamp

1. Introduction

Slip clamp designed to use for hanging Coiled tubing temporarily. When need to repairing Coiled tubing surface equipment or cutting it, slip clamp can fix Coiled tubing to preventing it falling. It can hold heavy equipment and convenient for Coiled tubing and using.

2. Feature

Hold heavy load

Convenient for assembly and using Convenient for lifting

3. Application

Using for hanging Coiled tubing temporarily

| CT(in) | Numeber | Suspended Weights(T) |

| 1.250 | L42 125100 | 20.0 |

| 1.500 | L42 150100 | 20.0 |

| 1.750 | L42 175100 | 20.0 |

| 2.000 | L42 200100 | 25.0 |

| 2.375 | L42 237100 | 25.0 |

| 2.875 | L42 287100 | 30.0 |

| 3.000 | L42 350100 | 30.0 |

Products

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve